Wiring Fire Alarm Systems: Initiating Device Circuits (IDC) and Signaling Line Circuits (SLC)

Fire alarm systems play a crucial role in safeguarding lives and property, and the reliability of these systems hinges on well-designed wiring infrastructures. At the heart of these systems are two essential types of circuits: Initiating Device Circuits (IDC) and Signaling Line Circuits (SLC). While both circuits are integral to the functionality of fire alarm systems, they serve distinct purposes and have different wiring requirements.

In this post, we’ll dive into the differences between IDC and SLC, explaining their roles, wiring standards, cable specifications, and application scenarios. Understanding these distinctions will help ensure the safety, reliability, and effectiveness of your fire alarm system.

Definition and Role of IDC and SLC in Fire Alarm Systems

Initiating Device Circuits (IDC)

An Initiating Device Circuit (IDC) is responsible for connecting the fire detection devices, such as smoke detectors, heat detectors, and manual pull stations, to the fire alarm control panel (FACP). The IDC acts as the first point of contact in detecting the presence of fire-related events and triggering alarms.

Key functions of IDC:

- Detecting changes in conditions (e.g., smoke or heat) via initiating devices.

- Sending an alert to the fire alarm control panel to trigger a response (such as activating alarms or fire suppression systems).

IDC Operation:

IDCs operate in two basic states: normal and alarm. Under normal conditions, the circuit remains closed with a specific level of current flowing. When a detection device activates, it opens the circuit or alters its resistance, triggering an alarm at the control panel.

Signaling Line Circuits (SLC)

A Signaling Line Circuit (SLC), on the other hand, is used in intelligent or addressable fire alarm systems. SLCs transmit data and commands between the control panel and addressable devices, which can include detectors, control modules, notification appliances, and more. Unlike IDCs, SLCs allow for two-way communication and can individually identify devices on the circuit.

Key functions of SLC:

- Facilitating communication between the fire alarm control panel and devices.

- Allowing the system to identify the exact location and type of activated device.

- Supporting complex fire detection and response strategies in larger or more sophisticated systems.

SLC Operation:

In an addressable system, each device connected to the SLC is given a unique address. When an event occurs (e.g., a detector senses smoke), the device communicates this information to the control panel. The panel then processes the data and determines an appropriate action, such as activating specific alarms or sending alerts to a monitoring station.

Wiring Standards and Cable Specifications

Given their different roles, IDCs and SLCs have distinct wiring standards and requirements.

Wiring Standards for IDC

- Class B Wiring: This is the most common wiring configuration for IDCs. It operates on an “open loop” system where devices are wired in series and the circuit terminates with an end-of-line resistor. In the event of a break in the circuit, devices downstream from the break will be disabled.

- Class A Wiring: In this configuration, the circuit forms a “closed loop,” allowing current to flow in both directions. If a wire break occurs, the control panel can still communicate with devices on both sides of the break, improving fault tolerance. This is a more reliable configuration than Class B but requires additional wiring.

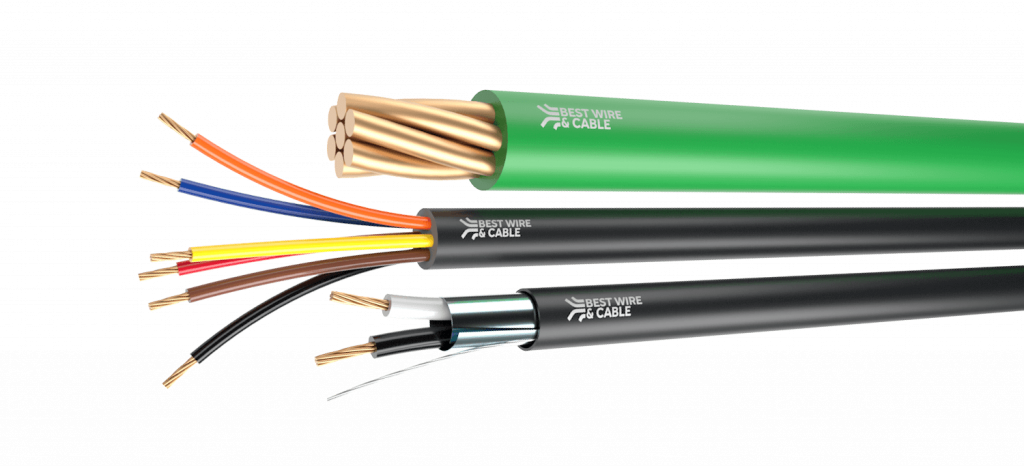

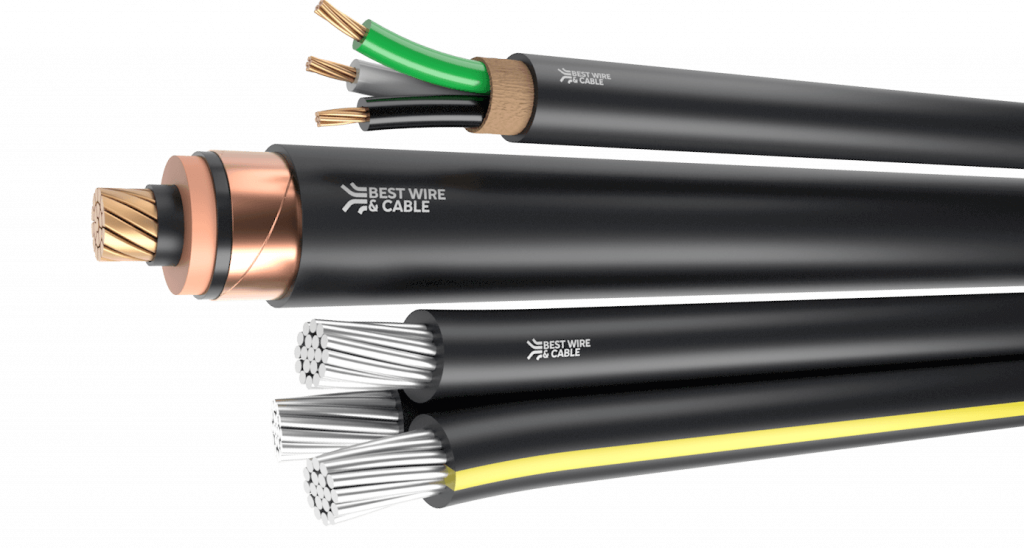

Cable Types for IDC:

Traditional IDCs typically use twisted pair cables, with standard fire alarm cables like FPLR (Fire Power-Limited Riser) and FPLP (Fire Power-Limited Plenum) being the top choices. These cables, available in sizes ranging from 16 to 12 AWG, are selected based on the specific needs of the system. The cables must meet National Electrical Code (NEC) and NFPA 72 standards for fire alarm wiring.

Wiring Standards for SLC

- Class B SLC Wiring: Similar to IDC Class B, devices are connected in a single loop, but in the event of a wiring fault, devices downstream will lose communication.

- Class A SLC Wiring: Devices are connected in a loop where both ends return to the control panel, ensuring full redundancy. In the event of a break, all devices remain operational as communication can route in both directions. This configuration is essential in mission-critical environments.

Cable Types for SLC:

SLCs, especially in intelligent fire alarm systems, often require shielded twisted-pair cables to prevent interference, as they carry low-voltage signals and data. FPL (Fire Power-Limited) and FPLP cables are the go-to choices, and it’s essential to choose cables that can handle the data load effectively while preserving signal integrity.

Application Scenarios: When to Use IDC vs. SLC

When to Use IDC:

Conventional fire alarm systems, which feature IDCs, excel in smaller buildings that have straightforward fire detection needs. Since conventional systems don’t need to pinpoint the exact location of a triggered device, IDCs are ideal in scenarios where cost-effectiveness and simplicity are more important than precision.

- Examples:

- Small commercial buildings

- Apartments or condominiums

- Older fire alarm systems with basic detection requirements

When to Use SLC:

SLCs are essential for addressable fire alarm systems. They are essential in larger, more complex environments where pinpointing the exact location of an event is crucial. The two-way communication between the control panel and individual devices also allows for enhanced diagnostics, such as identifying device health or performing remote tests.

- Examples:

- Hospitals and healthcare facilities

- High-rise office buildings

- Industrial complexes

- Schools and universities

Ensuring Safety and Reliability in Fire Alarm Systems

Both IDC and SLC circuits are vital for ensuring the functionality and reliability of fire alarm systems, but they operate under different principles and cater to different needs. IDCs provide reliable basic fire detection, while SLCs support more advanced communication and flexibility in system design.

Key Considerations for Reliable Fire Alarm Wiring:

- Use NEC- and NFPA-compliant cables to ensure system integrity.

- Choose the appropriate class of wiring (Class A or Class B) based on the size and complexity of the system.

- For larger, addressable systems, prioritize shielded cables to prevent signal interference in SLCs.

- Regular testing and maintenance of wiring infrastructure are essential to guarantee that both IDC and SLC circuits operate effectively in the event of an emergency.

Conclusion

Understanding the differences between IDC and SLC circuits is crucial for designing effective fire alarm systems tailored to a building’s safety needs. While IDCs offer basic detection and alarm functions, SLCs provide advanced communication and monitoring for enhanced control and safety. Selecting the appropriate wiring configuration and cable types ensures your fire alarm system operates reliably and efficiently, delivering vital protection during a fire.

View BWC’s Fire Alarm Products